Remember when your kids annoyed you by responding to everything you said with “Why?” Well, there was a genius to that tactic only children can impart. The 5-Why Analysis is a method used to determine and understand the root cause of a problem by repeating the question “why?” five times. Each answer forms the basis of the next question.

There are no hard and fast rules about what questions to explore, or how long to continue the search for additional root causes (e.g. asking “why?” seven or eight times instead). Therefore, the outcome of the analysis will always depend upon the knowledge and persistence of the people involved.

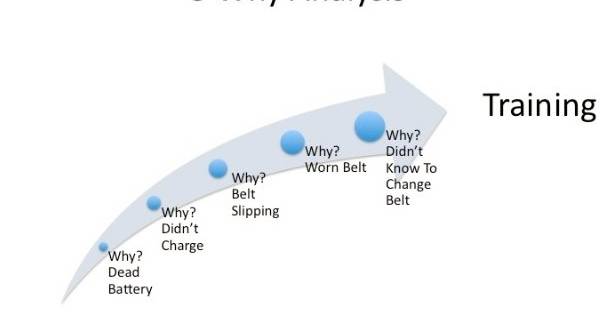

Here is a relatively simple example of Why Analysis:

Problem: The car will not start!

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

Just as annoying children so often do, it would be easy to continue asking “why?” in order to delve even deeper into the problem. However, five repetitions will generally suffice in leading to a root cause.

About Why Analysis

It is important to note that the determined root cause should almost always point toward a process that is not working well or does not exist, rather than something simple and generally uncontrollable such as “There wasn’t enough time.” Answers that are out of our control are not helpful; further in most cases what you will discover in your 5 Why Root Cause Analysis is a failure of process, which is the ultimate goal. You can’t manage and improve what you don’t know.

The developer of the 5-Why Analysis method Sakichi Toyoda was head of the Toyota Motor Corp who used this method to great effect. Toyoda has some helpful tips and strategies to think about when performing “ Why Analysis”:

- Use paper or whiteboard instead of computers

- Writing the issue helps you formalize the problem and describe it completely. It also helps a team focus on the same problem

- Look for the cause step by step. Don’t jump to conclusions.

- Base our statements on facts and knowledge; not conjecture.

- A root cause should never be something as simple as “human error” or “workers’ inattention”

The Why Analysis can be used in day to day business life, and is especially helpful when dealing with persistent problems that never seem to go away. Stubborn and recurrent problems are often so because they contain deeper issues, and “quick fixes” only solve the surface issues.

Need help dissecting and solving a recurring problem safety or employee injury problem? Don’t hesitate to call us at (914) 357-8444. We have been invited into thousands of businesses to break down their challenges and help solve for “x” , usually high insurance costs driven by claims. We will help you get to the why that much quicker. Time is money, gives us a call.